High Performance Force-Feedback Devices

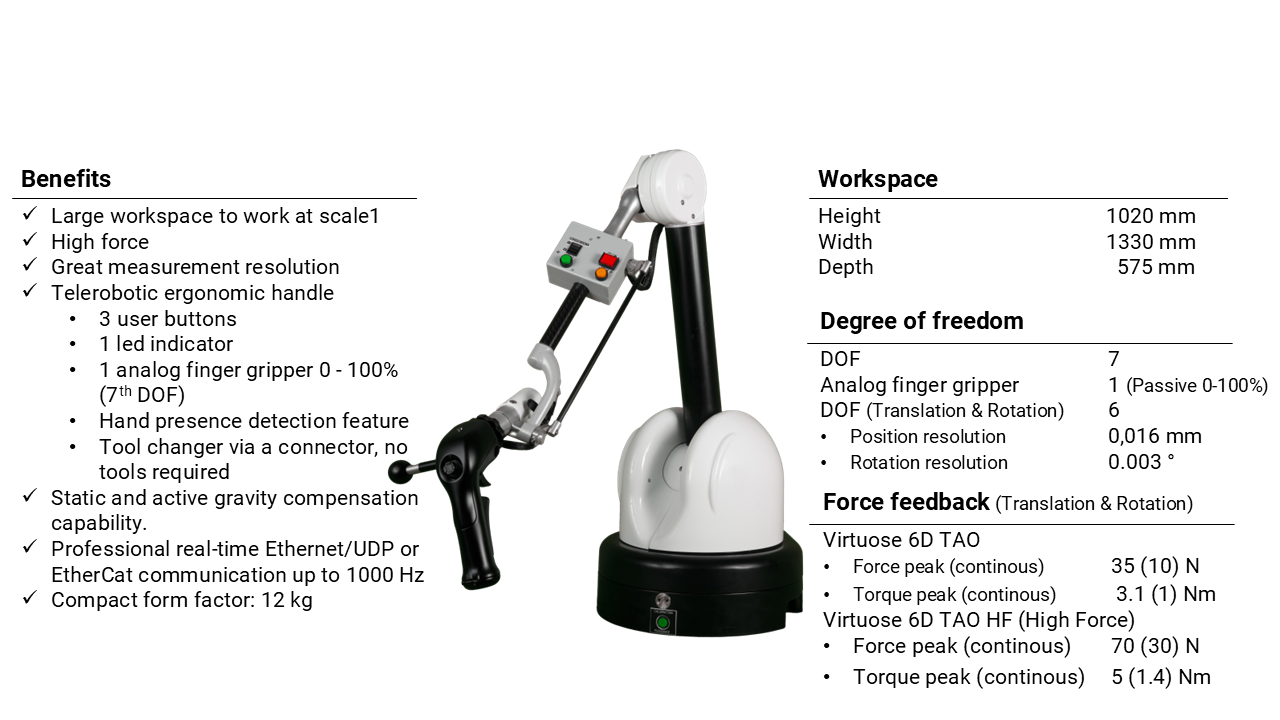

Virtuose 6D : TAO & HF TAO

Large workspace, high force & , with 6 degrees of freedom all with active force-feedback

The high performance tool

The Virtuose 6D is the only product on the market combining a high force feedback in the 6 degrees of freedom with a large workspace. The Virtuose 6D TAO was developed in collaboration with our customers, to answer the needs of teleoperation and remote handling applications, moreover it is suited for scale one manipulations, for instance in simulation and virtual reality.

Standard ergonomic handle

The ERGO handle of the Virtuose 6D has 4 user buttons, 1 led indicator, 1 analog finger gripper 0 - 100% acting as a 7th DOF, and a hand presence detection.

and DIY handle capability

The handle is replaceable, through its end effector tool changer via a connector (no tools required) which allows the use of different kinds of objects in order to replace the standard handle. For instance, you can use 3D printed objects to simulate your operation with even more realism!

Standard and upside-down position capability

Virtuose 6D TAO is used in standard position for telerobotics projects.

However thanks to its design and the static gravity compensation, it is possible to use the Virtuose 6D in an upside-down configuration with your custom handle and without impacting the level of force-feedback.

Find the perfect version of the VIRTUOSE for your application

Should I select Virtuose 6D TAO or Virtuose 6D HF TAO ?

High Force in the same form factor! Did you know that all the VIRTUOSE range of products are available in both Standard and in High Force Versions? The High Force Version, allows to triple the level of continuous force feedback available on the force-feedback device with same product form factor. High Force version is predestined for applications in need of a high level of force-feedback. High Force version is especially recommended in industrial robot teleoperation.

Freedom of Integration

With the Haption Low Level Software API

The same Software API, for all Virtuose and Desktop, enables programmers to benefit from high versatility when working on various applications.

Drivers (binary and/or source code) available for:

C++, C, ROS™, ROS2™

Python™ for IPSI™, CHAI3D™, ODE™, Matlab Simulink™, LabVIEW™

Available platforms :

Microsoft Windows

Linux

Comphehensive documentation enables developers to implement the communication protocol between Haption force-feedback devices and user control software. Please note, source code for the API is not included as part of this offering.

Each Haption haptic device is delivered with an easy to setup Demo that permits the user to test the product when it is received, and then at any time.

The device are also compatible with our range of software solutions, which allow you to directly use the device in CAD software to perform assembly simulation and in 3D game engines to generate even more realistic immersive experiences.

Dedicated plug-ins for: 3DExperience™, Catia™ & Delmia™ V5, Solidworks™

Solutions for Unity™ (Unity Technologies), Unreal™ Engine (Epic Games), and other real-time interactive simulation platforms by our Partners : LS Group™, Tree-C™, TOIA Ltd™, …

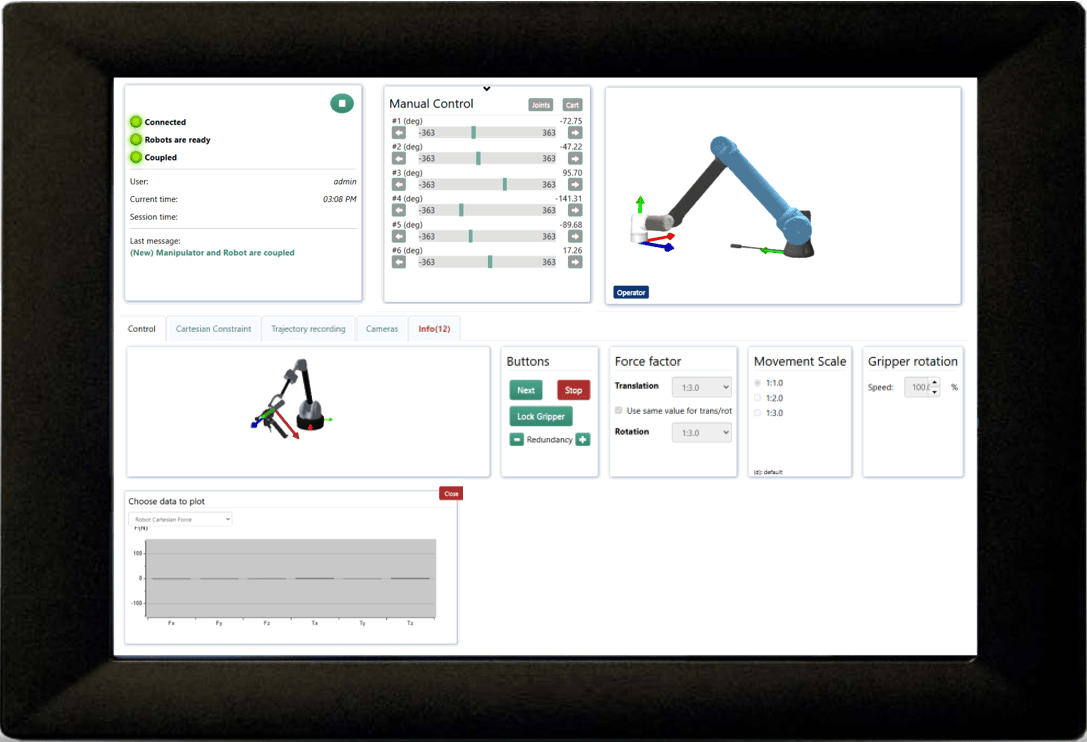

Deploy Robotics Faster with Minimal Integration

With Haption TeleRobotic EXtender

TREX is the Haption generic teleoperation controller for an easy integration to control industrial robots.

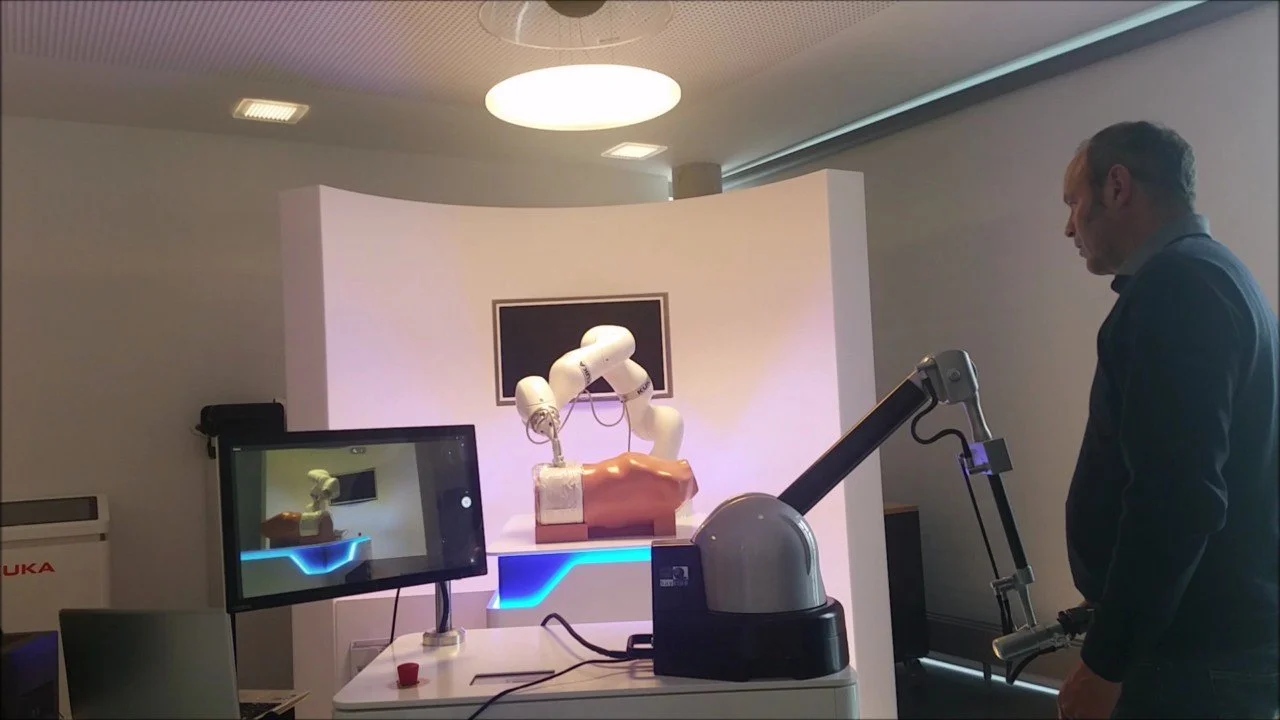

Force feedback is all about giving the user a better awareness. When performing robotic system remote control, it is important to have as much feedback as possible: a vision system to give you the seeing, potentially a microphone to help you hear the noise of the distant environment, and importantly a force-feedback manipulator to feel both robot movements and robot environment.

TREX, provides an immediate solution, with No-Code, to integrate force feedback teleoperation in a robotic system.

Connecting the Haption Force-Feedback Device to your Robotics system

Discover how Haption force-feedback devices are used in real robotics applications

Explore real-world examples of how our customers use Haption force-feedback devices to control robots from various third-party vendor robots, including Fanuc™, Kuka™, ABB™, Stäubli™, Doosan™, Universal Robots™, Franka™, Agile Robotics™, Kinova™, and more in nuclear, medical, industries and research applications.

Discover how our customers use Haption force-feedback devices to control third-party robots such as Fanuc™, KUKA™, ABB™, Stäubli™, Doosan™, Universal Robots™, Franka™, Agile Robots™, Kinova™, and custom robot, in nuclear, medical, industrial, and research environments.

Connecting the Haption Force-Feedback Device to your 3D Simulation

Want to interface Haption device with your 3D parts ?

Since 2004 Haption is a partner of Dassault Systèmes (3ds™) offering the software plugins for Solidworks, Catia™, Delmia™ and 3DExperience™ to enable users to perform assembly simulation.

Want to interface Haption device with your 3D simulations ?

Our devices are used with third parties simulation software framework enabling the use of 3D game engines to generate even more realistic immersive experiences. Among them : Unity™, UnReal™, …

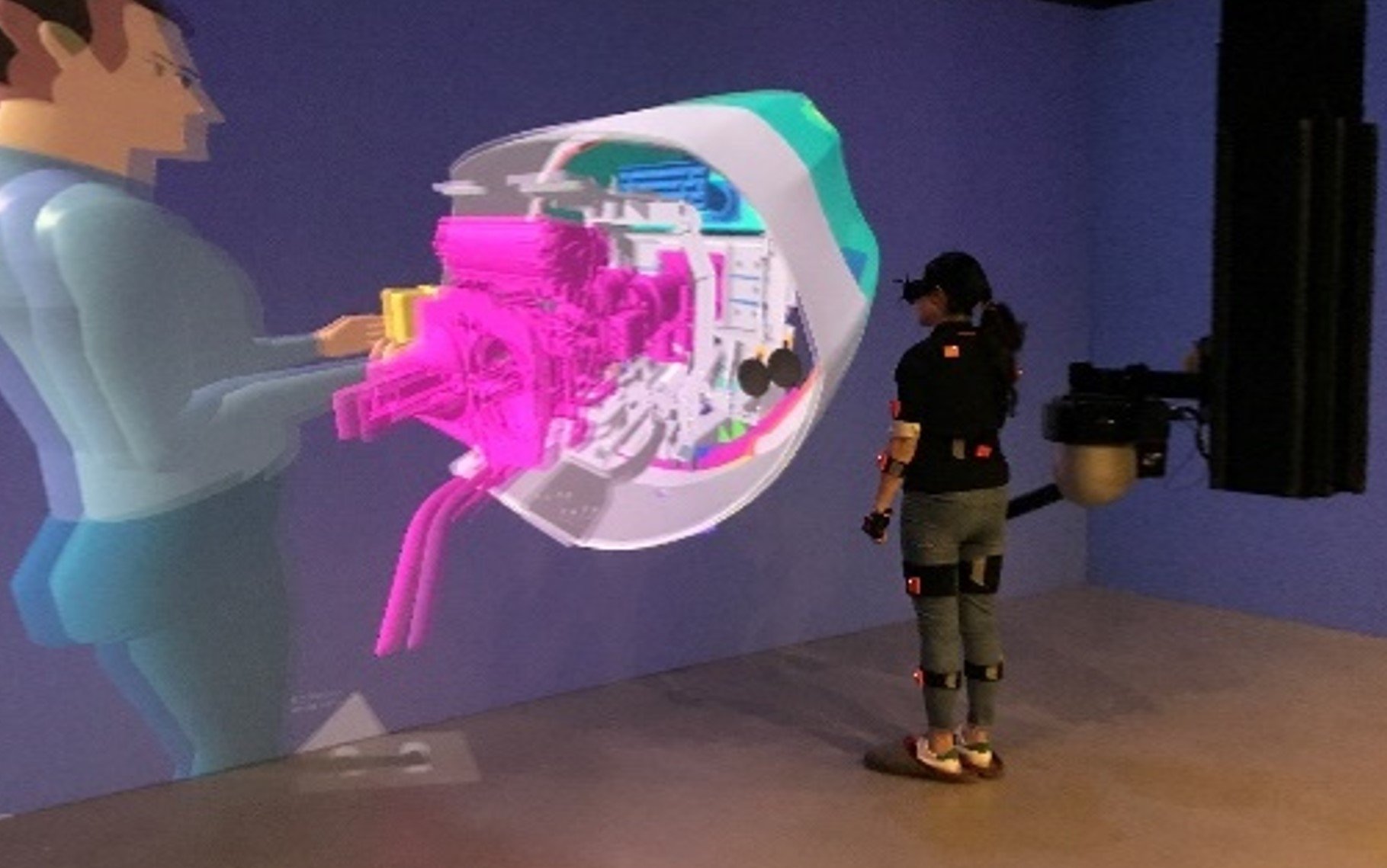

Extra Large Workspace Immersive Simulation

Virtuose 6D mounted on the extra large workspace motorized carrier Scale1

Better, bigger, stronger

The Scale1 is an extra large workspace motorized carrier platform which enables the workspace of a Virtuose 6D haptic device to be extended. The force feedback of the Scale1 is therefore performed through the Virtuose 6D, the final solution becoming as such the haptic interface with the biggest workspace in the world.

The Scale1 is born from the will to escape from the restricted space of a standard haptic interface. In a few years, it became a masterpiece of engineering, installed at the most prestigious laboratories and companies. The Scale1 is considered the most upscale force-feedback product.

The Scale1 is mainly used in two different applications. On one side, the industrial companieswilling to simulate with as much realism as possible their assembly operations, maintenance processes, accessibility verifications, or their ergonomic assessments, in advance of the manufacturing phases, in conjunction with the prototyping steps. On the other side, the laboratories and universities decide to use this state-of-the-art haptic device to further interact with the immersive environments and push the acquired knowledge on human behaviors, cognitive science and different study topics which are using virtual reality as a vector.

The Scale1 design is entirely customizable. We can adapt it to the size of your room, to the size of your screen or to the dimensions of your CAVE. It is designed in different versions, from 1 to 3 degrees of freedom, and can carry one or two Virtuose 6D RV. A recent version even supports a seat for the user, allowing him to literally fly inside the immersive environment!

Most will describe the Scale1 as state-of-the-art in terms of haptic device. Do not hesitate to contact us to study the implementation of a Scale1 in your environment or for your specific project.